Supply Chain Performance Management – Gaining visibility into operations

A recent Aberdeen Report, released in March 2011, acknowledges that the increased complexity of global supply chain has affected the performance of many organizations through longer lead times, excessive pipeline inventory and the need to control downstream and upstream logistics. This in turn lead to increased supply chain management costs and activated a critical need to better manage their excessive inventories and search ways to drive costs down, while enabling faster and more efficient response to customer needs ( Heaney, 2011).

While reducing costs by driving down excessive inventories and rapidly responding to business disruptions has become critical, the report shows that gaining visibility into supply chain processes has become of paramount importance. Based on this assumption Aberdeen has used a set of 4 metrics to determine Best-in-Class (top 20% of aggregate performance scores), Industry Average (middle 50% of aggregate performance scores) and Laggard (bottom 30% of aggregate performance scores) performers in terms of supply chain visibility excellence.

A recent Aberdeen Report, released in March 2011, acknowledges that the increased complexity of global supply chain has affected the performance of many organizations through longer lead times, excessive pipeline inventory and the need to control downstream and upstream logistics. This in turn lead to increased supply chain management costs and activated a critical need to better manage their excessive inventories and search ways to drive costs down, while enabling faster and more efficient response to customer needs ( Heaney, 2011).

While reducing costs by driving down excessive inventories and rapidly responding to business disruptions has become critical, the report shows that gaining visibility into supply chain processes has become of paramount importance. Based on this assumption Aberdeen has used a set of 4 metrics to determine Best-in-Class (top 20% of aggregate performance scores), Industry Average (middle 50% of aggregate performance scores) and Laggard (bottom 30% of aggregate performance scores) performers in terms of supply chain visibility excellence.

- % Orders received from suppliers complete and on-time;

- % Orders delivered to customers complete and on-time;

- % Change in landed costs per unit shipped;

- % Change in supply chain execution cost from revenue.

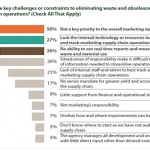

Among the most popular approaches employed by organizations to overhaul their supply chain processes and gain better visibility are:

- Streamline processes for easier monitoring, enhanced usability, or efficiency;

- Improve internal cross-departmental visibility and integration into supply chain transactions and costs;

- Improve timeliness and accuracy of data exchange about supply chain transactions;

- Increase B2B connectivity / visibility into supplier side processes with supplier, trading partners, carriers and managed service providers.

References

Image Source:- Heaney, 2011 (Aberdeen Report)

Tags: KPI, Logistics performance, Report Analysis, Supply Chain Performance