Outsourcing: most important factors influencing success

Outsourcing can be defined as “the strategic use of outside resources to perform activities traditionally handled by internal staff and resources”. According to Griffiths D., “outsourcing is a strategy by which an organisation contracts out major functions to specialized and efficient service providers, who become valued business partners”.

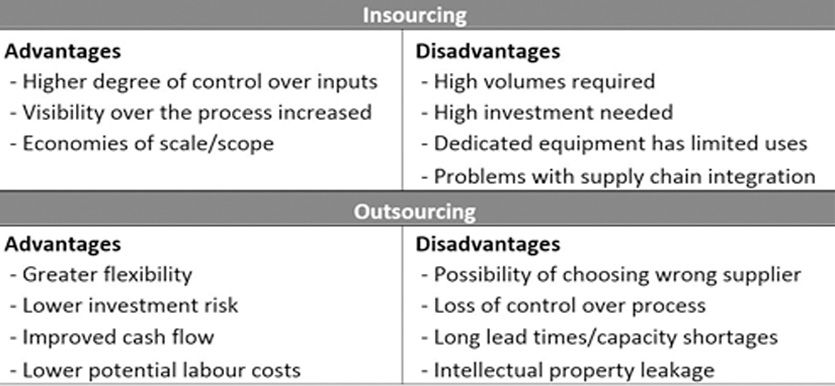

A company may choose to insource or outsource. Insourcing means that a company makes internally a particular material that it needs for its operations. Outsourcing means that it buys the material from an external supplier.

Insourcing and outsourcing occur when the decisions are made to reverse past buy-or-make decisions. Procurement managers have to use a variety of knowledge for the insourcing-outsourcing decision. Their essential approach is to analyse and compare the benefits of insourcing and outsourcing.

The sourcing decision is important because it affects costs, but it also defines the boundaries that a company draws around its operations. Companies are likely to retain internally those operations that are considered part of their core activities, while they are more likely to outsource activities considered rather marginal.

Image source: Monczka, R., Handfield, R., Giunipero, L. and Patterson, J. (2011)

Nevertheless, for this important decision, managers should also consider a variety of other factors which go beyond costs, such as supplier’s competency, quality, delivery time, risk mitigation, technology, reliability and continuous improvement.

Companies have always hired contractors for specific types of work, or to reduce their workload, and have formed long-term relationships with companies whose capabilities complement or supplement their own.

There are many whys and wherefores that might influence a company’s decision to outsource, such as:

- The external supplier has a better capability;

- Freeing resources for other purposes;

- Reducing and controlling operating costs;

- Selling assets to the provider equates to an infusion of cash;

- Risk reduction;

- There is a lack of internal resources;

- Out of the desire for more focus on core business aspects;

- Economies of scale;

- Benchmarking.

In the early days, the most common reasons to outsource were cost or headcount reduction. In today’s world, the drivers are often more strategic, and focus on carrying out essential value-adding activities in-house, where an organisation can best utilise its own core competencies. Unfortunately, rarely is there a clear organisational focus for determining which activities are core activities or for determining the strategic impact.

The critical areas for a successful outsourcing programme are:

- Understanding the company goals and objectives;

- Having a strategic vision and plan;

- Selecting the right, high quality supplier;

- Having a properly structured, effective contract and contract monitoring;

- Maintaining a good relationship with the supplier.

An important part of managing outsourcing is the consideration of potential exit strategies. There are many instances where outsourced services have been taken back in-house – clear evidence that even if companies outsource they can eventually retain long-term control.

Strategic objectives, such as outsourcing initiatives, must come from the top levels of a company. It is essential that both the company and the supplier have a clear and shared understanding not only of the specification but also of the goals and objectives, and that this understanding is translated into a workable strategic plan. Following the careful and rigorous procedures necessary for appointing an external supplier, the contract should be well-designed and mutually acceptable. Managers are looking ahead and are aware of the responsibility for guaranteeing the success of their company’s outsourcing initiatives, making sure that it does not stop when “the ink has dried on the contract”. Unfortunately, this has not always been the case. A mixture of uncertainty combined with a lack of attention to critical details has created a scenario where 25% of outsourcing contracts will be re-negotiated or cancelled.

On-going relationship management is important and top management must stay involved during the implementation of the contract. Not only should there be a clearly defined escalation procedure, but management should meet at appropriate intervals to discuss the outsourcing relationship. Meetings should also be held at the operational level to address the workings of the outsourcing contract in practice, to identify and resolve any issues along the way, and agree on changes to ensure continuous satisfaction.

References:

- Baily, P., Farmer, D., Crocker, B., Jessop, D. and Jones, D. (2010), Procurement, principles and management 10th Edition

- Griffiths, D. (n.d.), The theory and practice of outsourcing

- Monczka, R., Handfield, R., Giunipero, L. and Patterson, J. (2011), Purchasing and Supply Chain Management

Image source:

Tags: outsoursing, Strategy, Supply Chain Performance