Shoe design in the context of mass customization

In today’s business world, enterprises have to meet the advanced demands for greener, more customized and higher quality products. This means they have to focus on smaller and more specific market segments of customer oriented products. Mass production is turning into ‘mass customization’, which can be defined as offering customized goods at a price close to that of mass production.

The main difference between the two concepts lies in their operating logic: on one hand, in the case of the MP, lower prices lead to increased sales, increased sales to higher volumes, higher volumes to lower costs and lower costs induce lower prices. On the other hand, in MC, customization leads to satisfied customer and continuous innovation, which lead to higher sales and higher profits. As a ‘bonus’, the customers are better understood.

Moreover, thanks to higher profits and increased customer knowledge, the company can offer more variety. Therefore, we might say that MP is efficiency-driven and based on scale economies, while MC is customer-driven and based on offering greater variety at affordable prices. Now that the concept has been defined, it is clear that previous performance measurement systems, adequate for MP, need to evolve in order to meet the new operating logic of MC.

In order for mass customization to be effective, new business models have to be introduced. According to these models, customers and other important parts of the supply can have a crucial role in the design process, if they interact with the designer of the product.

Focusing on the shoe industry, it is important to note the key factors that are taken into account when buying a pair of shoes. First, there is the style of the shoe, which obviously has a direct impact on the customer. Another important issue is the fit, a prerequisite for footwear comfort, as misfits can result in foot injuries and deformities. The third dimension of shoe customization is represented by its function: the most important characteristics are the flexibility, the shock absorption and the thermal conductivity.

A special module has been created in order to assist the shoe design process. Now, main ‘actors’ of the company and of the industry supply chain (product and production engineers, customers, suppliers, retailers etc.) can develop the design of a new shoe altogether. This process considers all the-above mentioned factors that customers think of when buying a new pair of shoes.

Shoe Design Support Module

The idea is to gather relevant information about customer requirements and market designs. If products meet these requirements, they are going to be successful. Gathering and organizing such data require an effective tool. Within the DOROTHY project (Design of Customer Driven Shoes and Multi-site Factory – a research project within the 7th Framework Program NMP that aims at transforming the European Shoe Manufacturing in order to strengthen Europe’s ability to compete in the global market), such a tool is being developed: The Shoe Design Support Module – “ShoeDSM”. It follows a client-server architecture of web services; for its implementation, the programming languages HTML, SQL, JAVASCRIPT and JAVA are used. An authorized user can easily access it through an internet browser which does not require special plug-ins or other extensions.

How does it work?

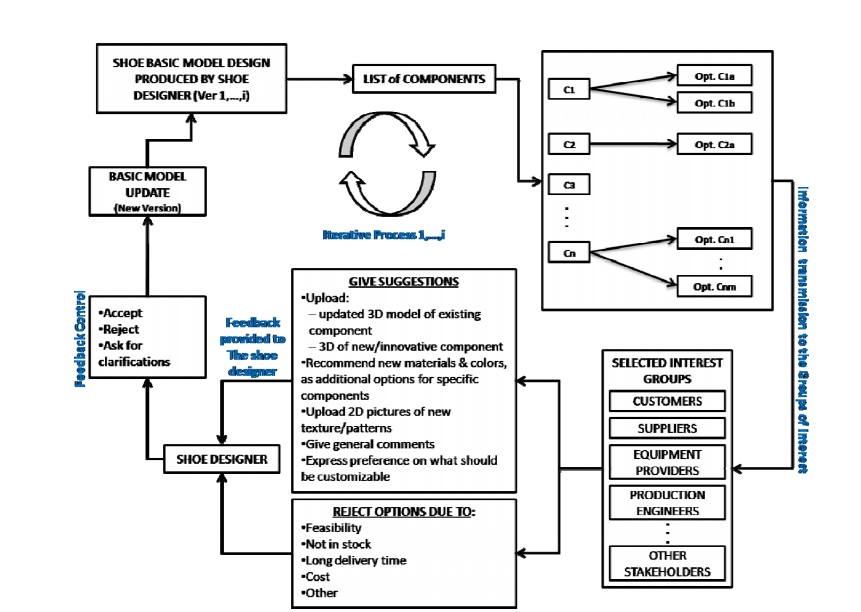

It uses Groups of Interest, the main being Designers, Customers, Production Engineers, Retailers and Suppliers. These are the most important groups, although further groups of interests can be added. This classification is necessary because users of different Groups have access to different sections of the tool; for instance, a Customer cannot delete a Basic Design.

The most important section is the Design section, as through this section Designers upload the new designs, making it possible for other users to view them and provide feedback, make comments, express likes or dislikes, or even suggest new ideas. The following figure can help better understand the use of this tool:

The shoe design process is supported by a software tool, namely the Performance Indicator Calculator (PIC), which meets the needs of the customer driven design, as it calculates the Performance Indicators Cost and Time for every customer product variant. It considers the needed resources and the specific production configuration (manufacturing, assembly and logistics, for instance). So, the cost and time values are based on the current situation at the production site, being thus as accurate as they can get. Especially in the case of mass customization, this tool provides added value due to the fact that synchronizes the customer, the product and the process data. Moreover, a total performance of the shoe will be calculated, derived from the synthesis of different components: weight, comfort, fitting, breathability etc.

As a great number of companies are shifting toward mass customization, the entire value chain has to be adapted to fit these new requirements. And performance management systems have to take this changes into consideration.

References:

- Pandremenos, J., Georgoulias, K., Chryssolouris, G., Jufer, N. and Bathelt, J. (n.d.), A shoe design support module towards Mass Customization

- Jufer, N., Daaboul, J., Bathelt, J., Politze, D., Laroche, F., Bernard, A. and Kunz, A. (n.d.), Performance factory in the context of Mass Customization

Image Source: Belkelme

Tags: Fashion performance, Performance Measurement, ShoeDSM, Software, The DOROTHY Project